“Our USP lies in creating customized Resin according to the customer’s requirement and application.”

About Our Company

PUMAX started with a single reactor that manufactured only one grade of unsaturated polyester resin with a capacity of 180 MT per annum. Today, we have a capacity of 9600 MT per annum and more than 70 grades of resin. Now, we are gearing up to open a state-of-the-art plant to ensure that our manufacturing and quality standards are as per international norms. The new plant would have a capacity of 24000 MT per annum.

Our plant is located in Medchal Industrial estate in the ‘City of Pearls’ Hyderabad, India.

We manufacture unsaturated polyester resins and different grades of resin. Our portfolio is designed to meet very specific needs with as much precision as possible. We invest a lot of our resources into research and development by understanding our customer’s industry in order to create raw materials of the utmost quality.

We want to provide our customers with an experience of procuring all the necessary raw materials under one roof. Therefore, we also trade in FRP accessories such as fiberglass mat, roving mat, surface mat, pigments, and accelerators.

Mission

We aim is to provide premium quality resins to our clients. We work hard to find out the ways that enable us to offer superior products at the most effective costs.

Values

We act with integrity and honesty and are committed to the values of responsibility, sustainability, and transparency. We focus on customer’s success and compete to win.

Our Goal

To play a significant part in the growth of the FRP industry by emphasizing the need to conserve our resources and maintaining an ecological balance.

Responsibility

We believe that with today’s rapidly changing environment it is essential for us to ensure that we minimize industrial wastage. We utilize biomass instead of coal for heating purposes and maintain a zero discharge policy.

Also, our electricity consumption is moderate as we use advanced machinery.

Milestones

1999 – Pumax manufactured only one grade of resin with a capacity of 180 MT per annum.

2001 – We expanded our capacity to 3600 MT per annum and also developing 10 grades of resin.

2004 – The grades of resin that we manufactured were now 30, catering to a variety of customer requirements.

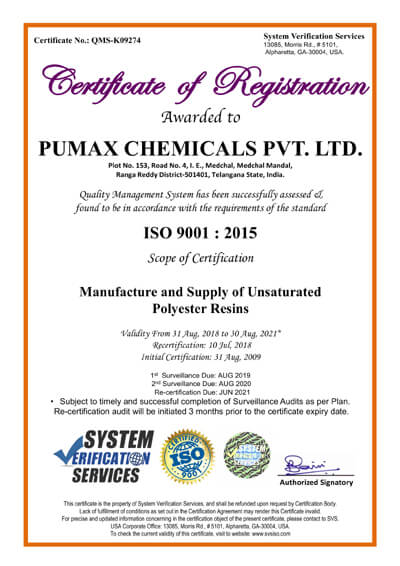

2008 – Pumax became an ISO- 9001 certified company. We started our own R&D plant for the development of new products and customization.

2010 – Pumax participated in International Exhibition. Developed resin for clear cast application.

2015 – We started our branch office in Bangalore. We started exporting to the South Asian Market.

2017 – We started our branch office in Ahmedabad and Delhi. We also expanded our customer base to South East Asia.

Our Team

Our team members are adept in their work and possess competitive skills that enable them to engage in extensive manufacturing activities on a very short time of notice. All of them work in close coordination in order to achieve the set target of work orders that enable us to attain customer satisfaction. Further, we have made provisions for regular skill development sessions for training for our team members in order to hone their skills and abilities that enable us to stay ahead in an environment of tough competition. Further, owing to our excellent infrastructural facilities, these experts and skilled workforce are capable to facilitate customization of our resins strictly as per the specifications detailed by our clients. We also have our own logistics team and can supply raw material to our customers in Hyderabad within a span of 24 hours.

Piyush Maheshwari

Managing Director

Archana Maheshwari

Director

Mr. Keshav Chandak

Head of Sales and admin

Mr. Vinay Mehta

Head of Marketing

Mrs. Krishna Veni

Head of Accounts

Mr. Vijay

General Manager Factory

QUALITY ASSURANCE

WAREHOUSE

Our warehouse is well-maintained, spacious, and voluminous that makes it capable to accommodate a bulk amount of resins. It is appropriately maintained and environmentally controlled to save the formulations from external harmful factors such as dust, moisture, varied conditions of weather, etc. We have internally divided our warehouse to store different products with safety and convenience of access.